Is your log splitter ram not retracting?

The piston might be blocked or bent. Removing the blockage or straightening out the ram will solve this.

Alternatively, you could be having pressure problems with the pump. In this case, you’ll need to check the hoses and the amount of hydraulic fluid.

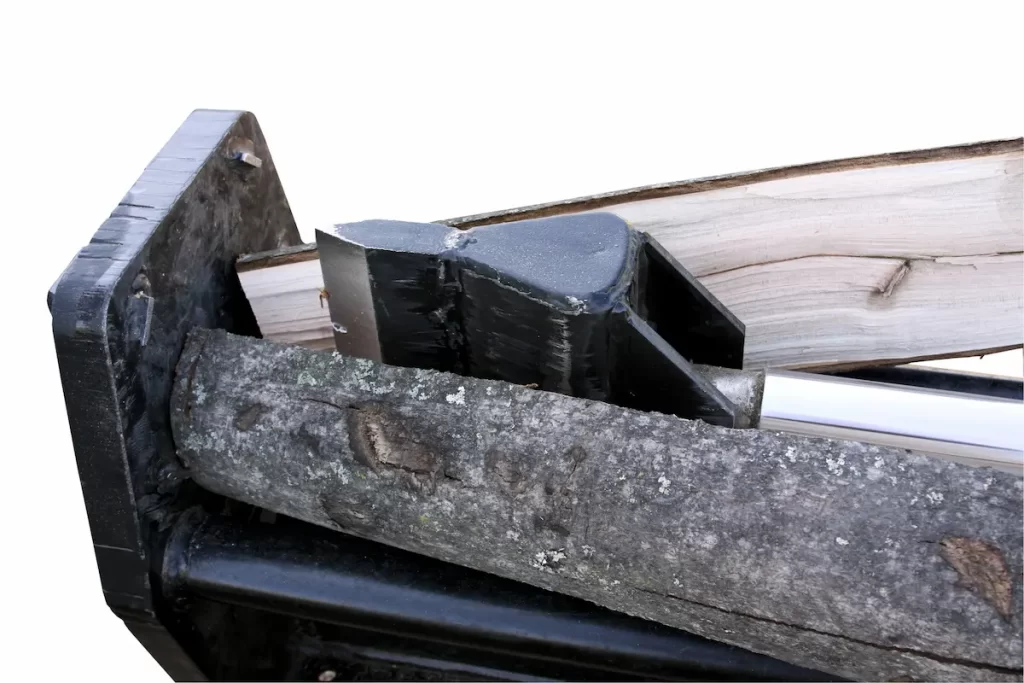

The ram is one of the most essential parts of the log splitter. It’s the part that will come down and slice through the wood.

Sometimes, the paper can get jammed in the printer. What causes paper jams, and how can you fix them?

You might be having a problem with your log splitter ram not retracting for a few reasons. This is common and doesn’t necessarily mean your log splitter is broken.

Keep reading to learn some simple ways you can solve these issues.

Related Reading: General Guide to Using Log Splitters

Table of Contents

Why is the Log Splitter Ram Not Retracting?

Troubleshooting your log splitter doesn’t have to be a challenging endeavor.

There are many parts to the log splitter, but a select few are often crucial to its performance.

The log splitter’s ram is a critical component.

Here are some suggestions for troubleshooting when the ram fails to return.

- Something is blocking the piston

- Bent piston

- Build-up of sap

- Pressure problem

- The log splitter is pointing downhill

Let’s look at some of these problems and how they can be solved.

Log Splitter Facing Downhill

Let’s start by discussing one of the most straightforward problems to fix.

Sometimes, the log splitter will be on a downhill slope.

This will put more force behind the log splitter ram as it breaks through the log.

However, it will make it hard for the ram to get back into the cylinder, as it needs to overcome the force of gravity.

All you need to do is put the log splitter on level ground, and the log splitter ram should return.

Blockage of the Piston

Blockage of the piston is one of the most common types of problems.

When chopping wood, splinters can come off and get caught in the piston.

Wood splinters around the piston can stop the log splitter ram from returning to the piston.

There is an easy way to see if this is causing the problem.

Start with turning off the log splitter.

This will ensure that you don’t accidentally hurt yourself should the log splitter start to move.

Next, make sure that you check the base of the piston.

You may find a wood splinter along the base, giving a clue this may be a cause for the log splitter ram not retracting.

There are a few ways that you can solve this. You might be able to wiggle the splinter free using your hands or a pair of pliers to grip the splinter.

You will need to remove the ram if you cannot remove the splinter just by wiggling it free.

To do this, you’ll need to follow these steps:

- Set it 150 mm forward.

- Remove the bolts that are holding the blade in place.

- Gently remove the piston from the machine.

As you are doing this, the splinter should fall out as well.

You can reinsert the piston into the machine, tighten the bolts, and it will go back into position.

It’s also essential to make sure that you look at the plastic spacers. Sometimes, spacers can fall and get stuck in the ram.

Bent Piston

When you remove the piston, it’s a good time to check its condition.

Sometimes, the log splitter ram not retracting due to the piston not returning because it has been bent.

What you must do will depend on how severely bent the piston has become.

You can test the angle of the bend to see if it can easily be straightened.

If the piston is slightly bent, you may be able to solve the problem by putting it into a vice.

This will apply pressure to the piston, bending it back into the right shape.

However, if the angle is more severe, you must replace the piston.

You’ll need to note the dimensions to ensure it will fit into your splitter.

Sometimes, you might be able to buy a suitable replacement from the manufacturer’s website.

You should also talk to someone knowledgeable at the store that sold the log splitter to you.

They can also help find the correct part information and may order it for you.

Build-Up of Tree Sap

One of the most common problems with a log splitter ram not retracting is a build-up of tree sap.

This is especially common if you are cutting through a lot of greenwood.

Fortunately, this is one of the most straightforward problems to solve.

All you need to do is apply some grease to the piston, as this will break down the sap.

You should notice the piston sliding back into the splitter a lot easier.

Pressure Problems

The log splitter uses a hydraulic system relying on pressure.

When the pressure is high enough in the chamber, the ram will go out, using the force to cut through the wood.

When the pressure is lowered, the log splitter ram will return to the splitter.

As you can imagine, a pressure problem can quickly become a big issue.

There are a few things that can be causing these issues.

Related Article: Log Splitter Troubleshooting: A Guide to Common Problems

Here are several items that require your attention:

Shipping Plugs

If this is your first time using the machine or if you have recently replaced the hoses, it is worth checking the shipping plugs.

Shipping plugs are designed to protect the hoses during transit.

To solve this problem, disconnect the hoses and remove the plugs.

Once you reconnect the hoses, the hydraulic fluid should flow through the hoses.

Shaft Coupling

Some parts might have shaken loose if you haven’t used the log splitter for a while. This is a common problem.

Tighten any loose nuts, particularly around the shaft coupling, which helps control the connection between the hydraulic pump and the engine.

A more complicated problem, but not difficult, is the gear between the two couplers has broken.

The upper coupler attaches to the motor, with the lower coupler attaching to the hydraulic pump.

When the gear breaks, the upper and lower couplers move independently instead of rotating together.

You will most likely need to replace the gear with both couplers.

This will entail either removing the pump or the motor. Removing the motor will reduce the loss of a large amount of fluid.

See this video to get a better understanding.

Change the Hydraulic Fluid

Hydraulic fluid doesn’t last forever. In most cases, you will need to replace it every six months.

You should consult with your owner’s manual to be sure of the hydraulic replacement schedule.

Check the Hoses

Finally, you might have a leak or blockage in the hydraulic hoses, causing the log splitter ram not retracting.

Look at the hoses for cracks or leaks while operating the log splitter.

Hydraulic fluid can become contaminated if there are cracks in the hoses.

Should you find a blockage or leaks, replace the hoses.

Check with the owner’s manual to get the proper part information, or check with the store of purchase.

Final Thoughts

In most cases, the log splitter ram not retracting into the cylinder is a relatively easy fix.

We have covered those simple troubleshooting recommendations and fixes.

However, the log splitter is a powerful machine that can cause severe injuries if not adequately maintained.

If you are unsure about any repairs, seek professional help.

There are many videos available that demonstrate ways to fix a log splitter ram that doesn’t return.

Some of these solutions are simple, such as those described in this article, while others require a higher skill level.

Be cautious when deciding on a solution to the log splitter ram not returning.

Just remember to be safe!

Enjoy living the outdoor life!