Log splitters are efficient and easy to use. However, if they’re not handled properly, they can quickly turn into dangerous tools. When using any type of machinery, like a log splitter, safety should always come first.

Once safety is ensured, using a log splitter properly and understanding how it works means getting the job done more effectively and more efficiently.

Sometimes people rush to start using their new tools only to find out a few months (or a few years) later that they’ve been doing things a little bit wrong.

I’ve put together this step-by-step safety guide on how to split logs while keeping your fingers intact. Here’s a summary of the process:

- Carefully follow the necessary safety precautions.

- Make sure the logs’ size is suitable for your log splitter.

- Service your log splitter.

- Split the logs.

- Properly store your firewood.

Not all log splitters are the same. Their mechanics might be somewhat similar, but they differ in their mode of operation and sources of power.

This is why we need to go into detail on some of the top-rated log splitters with a variety of different machines.

How To Split Logs: Our 5 Tips

Step 1: Safety Precautions

You need to make sure you’re safe and that your machine is protected from any form of damage. After all, you don’t want to lose a limb.

It doesn’t matter whether you’re using a manual or gas-powered log splitter; these safety precautions are paramount:

- Take off all jewelry before operating a log splitter. Especially necklaces and lockets, as they can get stuck in the machine and reel you in.

- Make sure your clothing fits. Baggy clothes can also get stuck and put you in danger.

- Put on your protective gear. A pair of goggles are needed to protect your eyes from flying splints. You’ll also need some ear muffs for your ears.

- No kids should be allowed near when operating the log splitter.

- Don’t drink and split. Never operate your log splitter when intoxicated.

- One log at a time. Don’t split two or more logs consecutively.

I know, I know, this is a long list of safety precautions, but you need to be extra careful when operating these machines. These machines lighten the load and it’s easy to start losing concentration after a bit of time.

Step 2: Logs should be of the right size

You need to be careful with this one. One small mistake, and you’ll break your log splitter.

After felling the tree, use your tape measure and chainsaw to measure and cut the trunk into smaller logs.

Here’s a quick tip: When cutting trees down to smaller chunks, don’t cut your tree trunks when they’re down on the ground. Doing so will only dull your precious chainsaw if it comes into contact with the hard ground.

Instead, use a log jack to first elevate the tree trunk before cutting away.

Another tip, use a firewood marker to mark the required dimensions. Put in your surveyor’s paint and roll on the logs. It’s more efficient than using pieces of chalk.

Once you’ve reduced the tree trunk down to reasonable logs, prepare them by leaving them out in the open for some time. Give them time to dry up.

Dry logs make high-quality firewood. They are also easier to carry and soft enough for log splitters to work on them efficiently.

The sizes vary with each machine. It’s best to check if your manufacturer gave the dimensions in the splitter’s guidebook.

Step 3: Service your log splitter

Servicing will vary with each machine. However, all modern log splitters will typically use hydraulics and pumps.

Servicing your machine before work not only ensures your machine’s efficiency, but it also reduces the likelihood of an accident to happen. No, you don’t need a mechanic.

Below is a simple servicing procedure you can follow:

- Check if any of your splitter’s components are loose, worn out, or damaged. Make sure you repair or replace them before operating your machine.

- Check if the hydraulic fluid is leaking. Pass a dry piece of cloth over any suspicious parts.

- Check and refill the hydraulic fluid. Make sure it is more than 75% full before operating the machine.

- Check and remove air bubbles trapped in the hydraulic cylinder. Do this by starting the machine without a load, and moving the wedge to and fro several times.

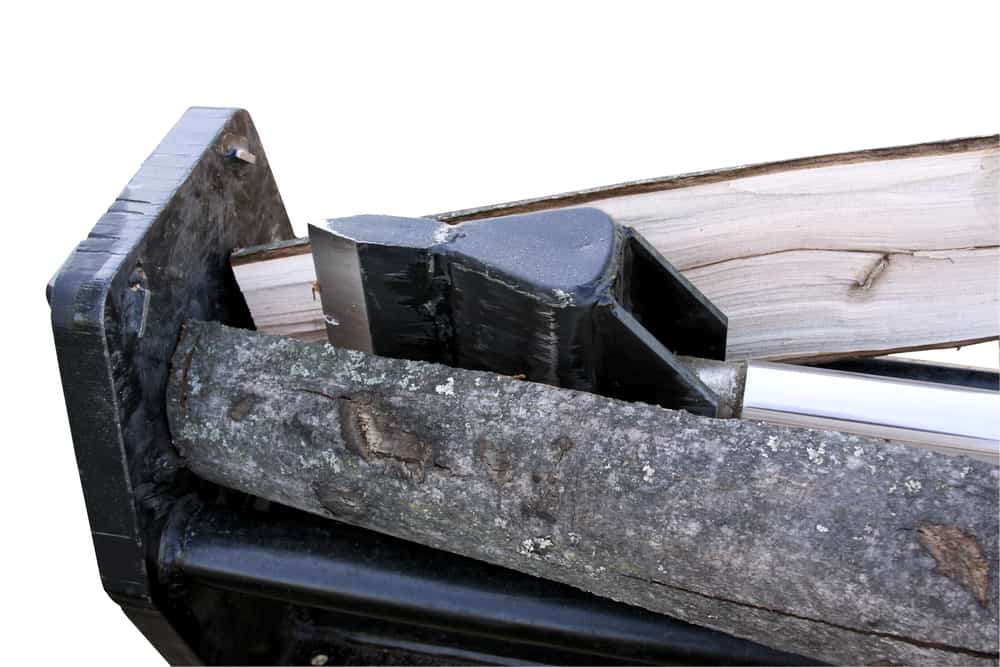

- Make sure the beam is lubricated. The beam is a long metallic shaft that pushes the log onto the wedge. Use engine oil to lubricate it.

- Make sure your log splitter is clean and ready for the day. Any leftover dirt and debris might damage the machine.

Step 4: Let’s split some logs

The procedure is different for manual and powered log splitters. We’ll go ahead and explain both.

Note: No matter which kind you’re operating, make sure there are no distractions when splitting. A slight deviation of focus and a terrible accident may occur.

Manual splitters

- Place your splitter on a clean, dry, and flat surface.

- Firmly secure the log to make sure it doesn’t fall off when splitting. Do this by tightening the jack and make sure the screw firmly grips the log.

- Operate your splitter and stop when the log is completely split.

- Retract the cylinder back to its starting position, loosen the tight grip, and unload the split firewood.

- Repeat the process down to the last log.

Powered splitters

- Make sure the splitter is on a flat, clean, and dry surface. Be extra careful with electric log splitters. Never operate one on wet ground. It might short circuit, or you might slip, fall, and get injured.

- Check the gas and oil levels before powering the machine ( I know you serviced the machine. Do it again to be on the safe side).

- Load your log onto the wedge dock. Make sure it’s in line with the wedge.

- Turn on the splitter and wait. Once it’s done, remove the pieces of split firewood.

- Retract the beam and load another log.

- Repeat the process down to the last log.

Step 5: Properly store your firewood

We’ve come a long way. People are usually so keen on following the process and forget to store and maintain their firewood properly.

Don’t throw away your efforts by carelessly piling your firewood out in the open. Instead, follow this process:

- Stack your firewood in a clean, accessible, and dry place.

- Ensure the place is elevated to prevent firewood from absorbing moisture from the ground. It also keeps your firewood out of reach of destructive insects.

- Make sure there is enough space for air circulation in between your stacks of firewood.

- Make sure your storage area is some distance away from your living quarters. Stacks of firewood are likely to attract small animals and creepy creepers.

Storing your firewood properly is crucial to get the most out of it and to avoid wasting a lot of hard work and effort.

Types of log splitters

There’s three main different types of log splitters available. Manual splitters are a tool that still require the body to generate force, like axe chopping

Then there are two main machine types known as gas and electric log splitters.

It’s also possible to build your own log splitter, but this requires some technical background and mechanical understanding.

Manual log splitter

Without a doubt, the manual splitter is the oldest log splitter in the fold. This is the first machine to save us from the good old axe.

As the name suggests, its efficiency relies on manpower, and therefore, it’s best used for splitting logs with small cross-sections. It’s also a log splitter you can have at home for simple everyday use.

If you’ve been around the “log splitting” game, you know there’s plenty of debate around using an axe vs. using splitter. Puritans swear by the axe while the other side swear by saving the wear and tear on your body.

From my perspective, if you’re still young and fit and don’t split wood for a living, you’re probably safe to keep using an axe.

But if you’re doing a lot of wood and log splitting, repetitive strain injuries are a real thing. Human bodies aren’t robots, so keep that in mind if you’re clinging on to that axe.

Gas log splitter

The gas log splitter is the most expensive log splitter in town. However, it’s for a reason. It’s also the most relied on and powerful log splitter. It can take on logs with large cross-sections.

And don’t forget you’ll also have to incur extra costs in fueling and maintaining the machine.

Electric log splitter

The electric log splitter is not as powerful as the legendary gas-powered splitter but can handle way more than a manual one.

It’s a medium-sized machine and usually smaller and not as heavy as the gas-powered log splitter.

Electric log splitters need to be plugged in and are, therefore, not portable. They’re mostly found in lumber houses.

Conclusion

Log splitters are a giant leap in efficiency when compared to hand-splitting logs with an axe.

However, they’re also more dangerous than axes, so you need to make sure you take proper safety precautions when using them.

Whatever you do, remember to only work on one log at a time. Working multiple logs is the quickest way to have an accident – and nobody wants that.