If you’re trying to determine the best hydraulic pump size for log splitters, there are two essential factors: the amount of power you need and how fast you want the splitter to operate.

Generally, most pumps require a pump with a plate number of 1, producing 2,500 PSI.

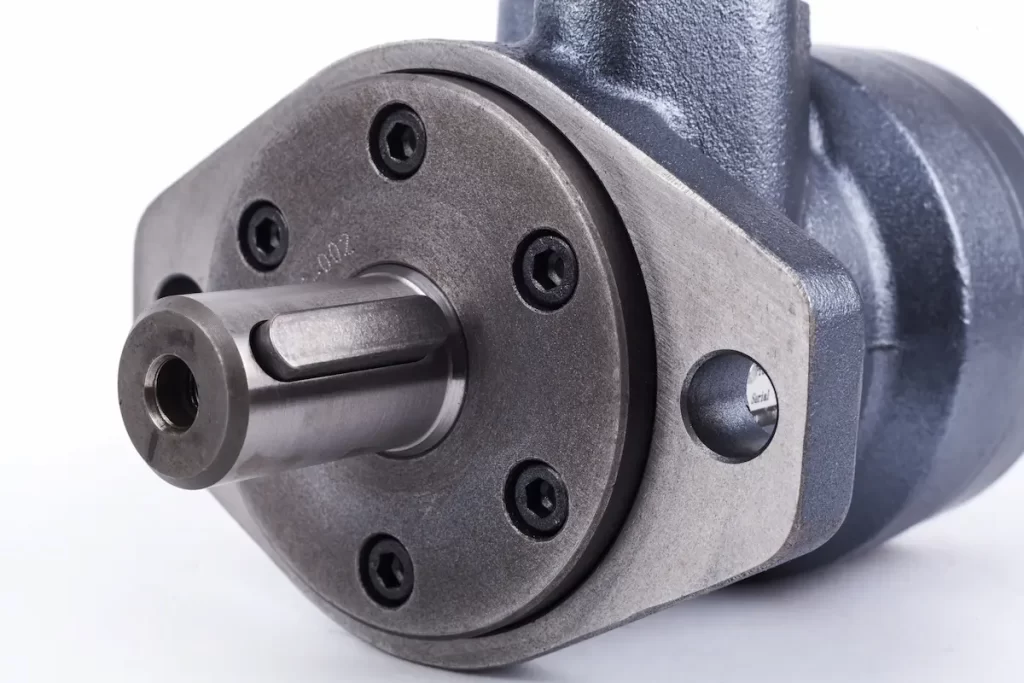

The log splitter pump is crucial as it maintains pressure in the cylinder, which controls the movement of the ram. But what is the ideal hydraulic pump size for log splitters?

Choosing the right pump is crucial for your log splitter’s performance.

However, with the plethora of available options, it can be challenging to pick the perfect one.

In this article, we will guide you on selecting the appropriate pump size for log splitters. Keep reading to learn more.

Related Reading: What is the Best Size Hydraulic Cylinder for Log Splitters?

Table of Contents

Getting the Right Hydraulic Pump Size for Log Splitters

There are plenty of things that you need to consider when trying to find your ideal hydraulic pump size for log splitters. These include:

- Size of the logs. When dealing with larger logs, more force is needed to cut through them. This means using a bigger log splitter, a larger hydraulic cylinder, and a thicker ram. You will also need a more powerful pump to do the job effectively.

- Speed. It’s worth noting that not all log cutters are created equal when it comes to speed. Generally speaking, the larger the pump used in a log cutter, the more fluid it requires. As a result, larger pumps tend to run slower than their smaller counterparts. For this reason, smaller pumps are often able to move at a faster pace than their larger counterparts.

- The cylinder you are using. You should consider the cylinder type used with the pump. It may indicate the required GPM for the pump.

- Engine size. You must ensure the engine generates sufficient horsepower to operate the pump effectively.

- Size of the hydraulic tank. It’s vital to ensure that the tank’s fluid capacity is compatible with the pump to prevent overheating.

When choosing a pump, it’s essential to consider its flow rate, which is measured in GPM, short for Gallons Per Minute.

A higher GPM indicates a more powerful pump. Additionally, you should also take note of the pump’s maximum pressure, which is measured in PSI or Pounds per Square Inch.

As a rule of thumb, most backyard log splitters utilize a hydraulic pump rated 11 GPM.

To operate such a pump, a 5.5 horsepower engine is required. Typically, a hydraulic log splitter pump generates around 2,500 PSI of force.

If replacing an existing pump, you can turn to the owner’s manual. This will tell you the technical specifications, making it easy to replace.

Related Reading: Brief Breakdown of Log Splitters and How They Work

Type of Hydraulic Pump

After determining the necessary power of the pump, it’s essential to consider the type of pump to purchase.

Although there are different options available, it’s generally recommended to choose a two-stage pump.

When it comes to this particular pump, it has been specifically designed to utilize two gears. This enables the pump to operate smoothly and efficiently, resulting in optimal speed.

If you’re curious about the inner workings of this type of pump, you may want to check out this informative blog post.

Once you have purchased a hydraulic pump, it is time to install it on your log splitter. The steps for installation can be found in the owner’s manual.

Adjusting the Pump to Suit Your Log Splitter

To achieve the desired results, you may need to adjust the pressure output of your pump. This is particularly helpful when working with wood of different sizes.

You can apply more force to larger pieces and get more speed for smaller pieces.

To adjust the pump’s pressure output, follow these simple steps:

- Start the engine. Allow it to start idling. This allows the hydraulic fluid to warm up.

- Put the splitter into neutral. This should stop the ram from moving. You’ll need to be careful to avoid sharp parts, like the end of the piston.

- Lower the guards. This should expose the pump so you can change the settings.

- Change the settings. You’ll need to use a flathead screwdriver to do this. If you want to increase the pressure, to get more power, turn it clockwise. If you want less pressure, turn it anti-clockwise.

- Raise the guards. This ensures that the engine and pump are protected from splinters.

- Take the machine out of neutral. You should notice the change immediately.

Most backyard log splitters operate on a standard pressure of 2,500 PSI. However, for thicker pieces of wood, the pressure can be increased to 3,000 PSI.

You should avoid extended use of high PSI to prevent excessive wear on the pump, which will require more frequent replacement.

Tips to Speed up a Hydraulic Pump

If you’re unhappy with the speed of your hydraulic pump, it’s possible to address the issue without purchasing a more powerful model.

Before spending any additional money, try these suggestions to see if they can help increase the pump’s speed:

- Use a three-way valve. This is a simple attachment you can add to the pump to make the forward stroke faster.

- Change the size of your cylinder. This will let you see an instant increase in the amount of speed. On the downside, you will have less cutting force.

- Increase the size of the rod. The bigger the rod, the less pressure it takes to get back into position. But it will take more force to push it out.

However, the effectiveness of these solutions is limited.

If you’re still experiencing issues, upgrading the pump may be necessary.

Keep in mind upgrading the hydraulic pump size for log splitters will require upgrading the engine and increasing the hydraulic fluid tank’s capacity.

Final Thoughts

It is crucial to ensure that you select the correct hydraulic pump size for log splitters, particularly if you are building the machine yourself.

Remember to know the size of the project as it relates to power, as well as the amount of speed to complete your cutting. Cylinder, hydraulic tank, and engine sizes should be considered.

However, if you stick to the standard 2,500 PSI models like 11 GPM, you should not encounter too many issues.

Be safe whenever replacing the pump and follow directions carefully.

Enjoy living the outdoor life!!!